Measurement and Analysis of Batteries for Electric Vehicles

Every day it seems we are inching closer to the vision of a more sustainable mobility with green power and electrified vehicles on the ground (NEV, BEV), but also on the water and in the air.

The mega trend of protecting the climate by using ‘sustainable solutions’ that reduce CO2 emissions is driving technologies such as high capacity/high-power batteries or H2-based fuel cells as the main sources of mobile energy. Moving away from combustion engines also requires a new way of thinking within test and measurement, including new safety concepts, new test environments, new types of sensors and measurement technologies, and adapted data analytics.

New Drivetrain Technologies – New Test Requirements

In search of sustainable, green mobility, HBK started facing challenges in development and testing of mobile energy storages for vehicles early on. As market leader in test and measurement, electrical power testing, sound and vibration and environmental testing, HBK has gained early insights into the many requirements and needs from industries, such as automotive and commercial vehicles, in terms of validating innovative energy storage and overall NEV concepts.

Batteries with voltages up to 1000 V in modern vehicles require an enormous range of tests, extended by special safety measures in handling dangerous electrical voltages and Lithium as core elements of the electro-chemical process. Within the test scope, HBK covers most measurement variables:

- Electrical voltage, current and power for performance and efficiency analysis

- Safety short circuit tests and optimized charging testing

- Force, strain, pressure and weight for mechanical durability and packaging analysis

- Temperature, flow, and pressure for thermal durability analysis

The testing of combustion engines includes up to 300 temperature measurement spots as well as highly dynamic torque, speed, and pressure measurements. With the integration of batteries and fuel cells, the number of measurement channels is moving towards the energy storage as the largest component in a modern drivetrain.

Why Measurement and Data Analysis?

In today’s electrified powertrain solutions, all aspects from single cell battery to battery packs are covered by virtual (simulation) and physical testing with the following typical scope:

- Long-term battery reliability testing, focusing on discharging/charging cycles (slow, fast), self-discharge including measurement of individual cell tensions and temperatures, and the overall power analysis

- Dyno testing focusing on power, efficiency, and reverse load feedback

- Environmental testing running specific use-case oriented mechanical load profiles on shakers, combined with climate chamber temperature cycling up and down

- Misuse and impact testing (overload, short-circuit, overheating, mechanical stress, defect)

- Structural integrity testing, starting with mobile vehicle testing for road load data acquisition (RLDA), summer/hot, winter/cold testing with transients

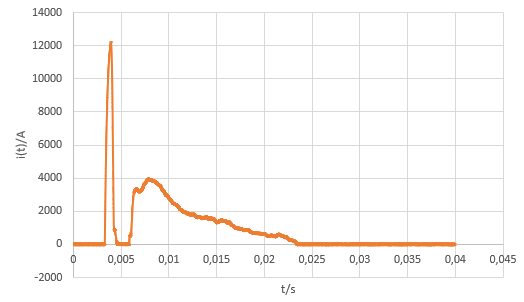

Battery Pyrofuse Short-Circuit Test

Qualifying the circuit breakers and pyrofuses of high-power traction batteries requires the ability to measure currents in the range of a few kiloamps with extremely high sample rate to catch the peak current. It also calls for the ability to measure currents of a few amps precisely and with high dynamics. And due to the high voltage, high currents and extremely fast risetimes it puts high demands on the used DAQ system with respect to EMI immunity, overvoltage protection, and isolation. One way to conduct short-circuit tests is to use non-linear current sensors and Genesis HighSpeed data recorders.

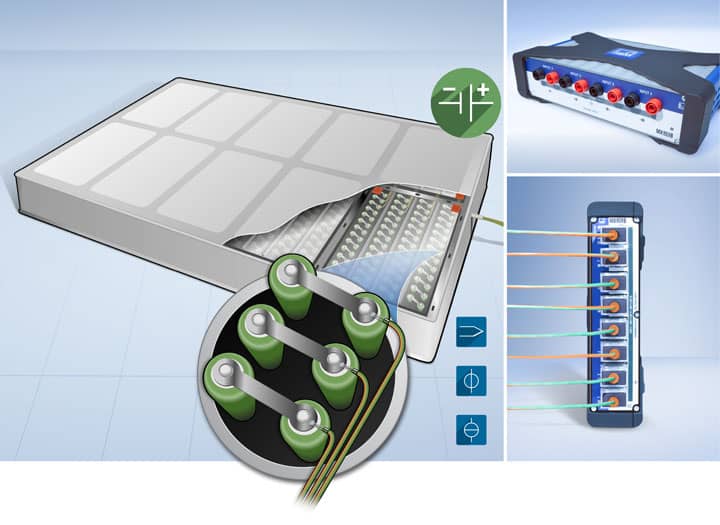

Pouch Cell Testing: Mechanical Testing of Batteries

Force transducers can help you understand how quickly battery capacities fade as they can be used to evaluate the stress on battery cells during charge/discharge cycles.

In the so-called pouch cell test, a force sensor measures the stress that occurs inside the battery under different charging conditions. This stress is relevant for the battery’s performance as it can lead to capacity fading or, in extreme situations, to the complete failure of the battery.

Learn about the most relevant characteristics of force sensor for mechanical battery testing. The white paper will also describe an easy way to estimate the measurement uncertainty in pouch cell tests.

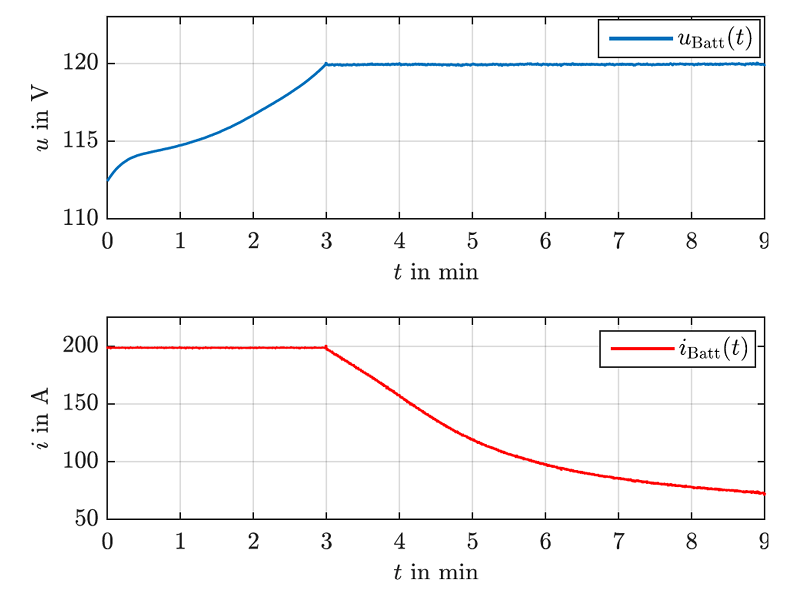

Electrical Qualification and Verification under Dynamic Load Conditions

Before a traction battery is introduced in the market, a qualification and verification of those systems is inevitable. A suitable test bench must cover a high voltage and current range as well as a high dynamic and it should be able to execute the necessary tests as realistically as possible and, in an application-oriented manner. For this purpose, the measurement techniques must be highly precise and dynamic.

How this can be achieved, and how HBK equipment can help here, you can find out here.

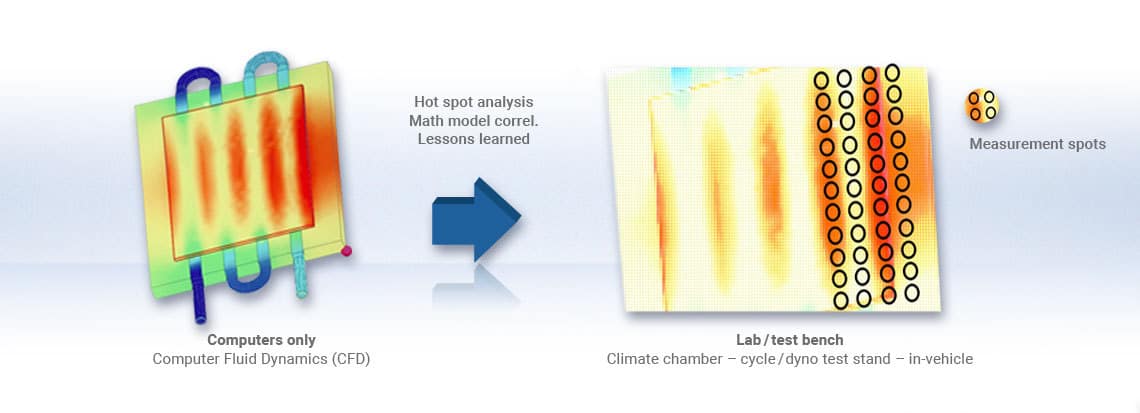

Battery Thermal Management

Batteries are the core and the largest single component of a modern, battery-driven electric vehicle (BEV) or new electric vehicle (NEV). It is about finding and validating the optimal key parameters for the complete setup.

The limited performance of lithium-ion batteries in extreme temperatures drives the complexity of thermal management systems with the supporting auxiliary aggregates and air-cooling paths. Too high temperatures may lead to self-destruction and even fire (thermal runaway). Extensive testing, and thermal validation especially, are therefore vital in the overall test setup.

Operational safety is one of the most important requirements. Expectations regarding service life vary from at least 10 years, 450,000 kilometers or a recharge target time of five minutes with super chargers. Also, the re-use of batteries and the second lifetime is an important topic.

Thermal management of battery life is crucial to key parameters such as speed performance, security, pricing and many more. Thermal analysis, therefore, requires numerous temperature measurement points with the highest demands: small measurement spots, maximum safety using double-insulated sense line, electrically isolated channels, non-contact plugs, apart from the typical ones with highest signal accuracy, and noise suppression.

Long-standing Expert in Thermal Testing

HBK develops and offers the necessary components for thermal validation measurement chains for years. These solutions are covered by electrical, optical, or combined – hybrid – measurement chains.

Already combustion engines must deal with the fact that power generates heat. With the electrification of mobility and the upcoming need to develop thermal testing methods also here, HBK looked at existing processes and refined them from a new perspective. Thus, all the experience and knowledge has been processed and adapted to also become a specialist for eMobility thermal testing and within this, for battery testing.

The HBK energy storage thermal testing system measures parameters including voltage, current, temperature, humidity, cooling flow, pressure, and talk-to-battery management system. Calculations are made for power, efficiency, hot spot monitoring, visualization, and analysis. Automation deals with test control and safety.

An HBK data acquisition and analysis solution provides thermocouple measurements for the exterior of the electric drive train and for investigation deep into the battery, including cell voltages, overall voltage, and current measurement. Universal inputs cover universal flow, pressure, humidity, and other required parameters.

HBK is your cost-effective, one-stop-shop solution provider for thermal, mechanical, and electrical test specimen analysis.