Enabling time synchronization for power substations

INDUSTRY

Substation Project – Energy/Power sector.

BACKGROUND

Our customer is a leading government utilities entity that has provided reliable and quality electricity and water since 1956.

To upgrade operations, security measures, and troubleshooting process, they wish to synchronize the time using the NTP protocol, and communicate with hundreds of feeder protection and control relays.

CHALLANGES

Managed layer-2 switches are required for efficient power management, monitoring, and control to ensure reliable network operation and safety. As the available supply voltage inside the bay/cubicle is 110 VDC, the switches must support this voltage. And due to the mounting constraints within the substation bay or cubicle, rackmount switches are not feasible, leaving DIN-rail as the sole mounting option.

A minimum of 21 copper ports is required for network switching, 20 for use and 1 for laptop connection in case of troubleshooting needs. The existing protection relays operate at 100base-TX, hence the switch can be Fast or Gigabit speed. Additionally, two uplink ports with a combo of Gigabit copper and Gigabit SFP slot are necessary. This totals 21+2 uplink = 23 ports.

Moreover, the solution should have user-friendly configuration and upgrade features to facilitate easy maintenance.

SOLUTION PROVIDED

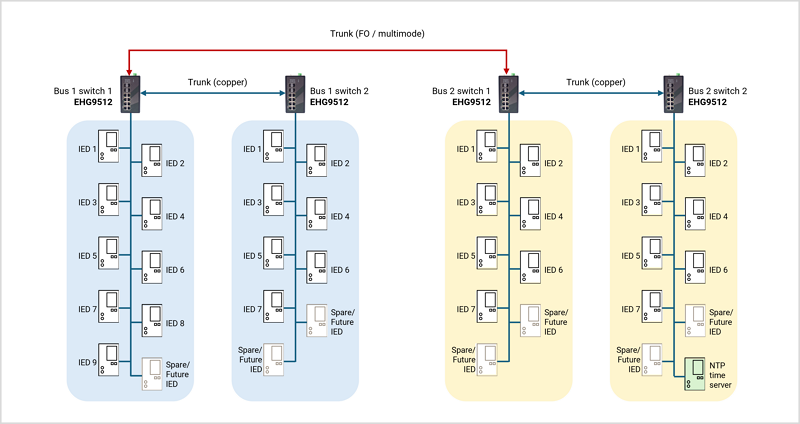

ATOP layer-2 managed IEC 61850-3 Ethernet switches EHG9512 offers 12 Gigabit ports each, including 4 SFP uplinks. There are 2 buses present in the substation, so each bus connects to 2 EHG9512 switches for a total port count of 24. See topology below for the actual port usage.

As an IEEE1588v2 end-to-end transparent clock, EHG9512 not only facilitates communications between IEDs and management, but also enables time synchronization with nanosecond-accuracy. IEC 61850-3 certification and IEC 62443-4-2 compliance ensure the reliability and security required for critical utilities. Finally, flexible remote management options such as through web browser, telnet, serial console, or a utility tool allow easy maintenance by substation staff.

RESULTS

Through collaborative efforts, we successfully helped our partner to implement an advanced and bespoke solution tailored to their specific needs. This enhanced system not only delivered superior performance but also achieved notable reductions in maintenance requirements. This accomplishment underscores our commitment to delivering innovative and impactful solutions that drive operational excellence and sustainable growth for our partners.

PRODUCTS USED

TOPOLOGY