HBM Wind Turbine Condition and Structural Health Monitoring

Take the holistic approach to ensuring the stability of wind turbine structures with HBM. Start by requesting our free white paper below.

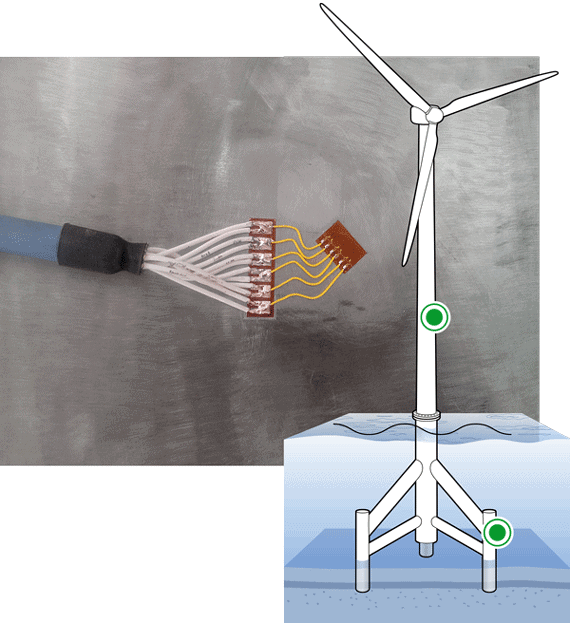

Condition Monitoring Systems for offshore wind turbine structures

A Condition Monitoring System (CMS) is a way of ensuring the stability of your wind turbine structures and components. CMS provided by HBM means identifying mechanical stress during measurements with strain gauges, displacement sensors,accelerometers and inclinometers.

A Condition Monitoring System (CMS) is a way of ensuring the stability of your wind turbine structures and components. CMS provided by HBM means identifying mechanical stress during measurements with strain gauges, displacement sensors,accelerometers and inclinometers.

A typical project includes installation of measurement equipment, measurements and reporting, ongoing support. Our offer includes fatigue and structural monitoring of components and structures above and below the waterline, on long term or short term basis.

- Validating theoretical design work

- Following industry guidelines

- Generating reliable data for structural assurance

- Ensuring a long and profitable lifecycle for your wind turbine generator (WTG)

Wind Turbine Testing and Condition Monitoring

“Wind Turbine Testing and Condition Monitoring” Free White Paper from HBM on Holistic Power Plant Management:

Collecting more pertinent data leads to cost optimisation and complex life time predictions.

What you will learn:

- What is the ROI of structural health monitoring projects?

- How can structural health monitoring help you to predict the life time of a wind turbine?

- What are the most beneficial measurement technologies used for structural health monitoring?

More information

Our company provides measurement products, installation and support for your fatigue and structural monitoring above and below the waterline. For monitoring on either long or short term basis, using condition monitoring systems and structural health monitoring equipment, our engineering team is here to support your projects.

Customer references

“It was the first time we used field measurements at this scale. To ensure that strain gauges were correctly mounted on our equipment, we decided to bring in specialists from HBM. The dialogue with HBM flowed very well. Going forward, we now have a much better idea of how we can take advantage of measurement technology”, says Mats Idoff, development engineer at Bromma Conquip.

More references and services we provide

Why Condition Monitoring Systems?

Condition Monitoring Systems (CMS) have increased in importance over the years. There are industry guidelines to follow plus the need to reliably understand how the structure performs in the short term for validation, and in the long term as an aid to minimize downtime. Increasing the overall reliability of the wind turbine structure (monopiles and jackets) is an important issue, especially considering potentially harsh conditions at sea and the unpredictability of seabed geophysics. Providing measurement data to demonstrate long-term reliability can assist with extending lifecycles. Our products and services can help you to achieve this.

Why Engineering and Services from HBM?

- Follow industry guidelines.

- Eliminate the uncertainties with the help of professional mechanical measurements with our engineers.

- Minimizing the costs by avoiding unplanned downtime.

- Increase the reliability of your structures.

- Create new business opportunities with us. How can the measurements we offer and your increased knowledge/understanding within this field help you to gain market share?

Having a closer look…

Although the trend is going towards a more holistic view of the wind power plant also in terms of measurements, it makes sense to also have a look at individual parts of the plant. As naturally, there are challenges and goals connected to different parts of the wind power plant:

Blades and rotor

Your goals:

- Increased efficiency in energy harvesting

- Ensured high quality

- Extended operational lifetime

Trends are going towards larger sizes of blades and rotor to gain efficiency in energy harvesting which also mean new challenges for the structures. What impact do larger blades and rotors have on the actual components as well as other parts of the structure?

Knowledge about other factors such as behavior of new materials and the impact of weather and lightning also need to be monitored and analyzed in order to ensure high quality.

Although structural health monitoring systems cannot predict the future, they can make it “measurable” and “predictable” to a certain extent.

Tower and foundation

Your goals:

- Decrease weight and complexity

- Ensure the construction techniques and materials used are optimal

- Monitor to prove long-term structural integrity during operation

The demand for lighter and more reliable structures creates a need to ensure that the tower and foundation can withstand harsh conditions on and offshore. How can you gain knowledge about how the structures behave? Are they fit for the job?

By learning more about the behavior of the structure and components, comparing measurement results and analysis of different types of structures, measurements can be a guide in the journey towards an optimized design. Data gathered can help prove the long-term structural integrity of your assets, helping with life-cycle extension projects.

Drive train and generator

Your goals:

- Increased reliability and efficiency

- Extended operational lifetime

- Improved planning for service and maintenance

As gearbox failure represent a big part of the wind turbine downtime, gaining reliability here is key. Also the efficiency plays an important part of the drive train and finding ways to increase it where measurements can help as a tool.

With the help of monitoring it´s possible to keep track of the behavior and health of the components, the potential breakdowns can be detected in time and prevent damage to your structure, even possibly increase it´s operational lifetime. This also helps with better and more efficient planning for service and maintenance.