How to Optimise Electric Vehicle Powertrain Testing

How to Optimise Electric Vehicle Powertrain Testing

In the car dealer showroom, the sticker on a new electric vehicle tells the potential customer two essential bits of information: “energy consumption” (in Miles per Gallon E-equivalent) and “the range” (how far the driver can expect to travel until the battery needs to be recharged). For the driver, consumption means lower cost; and longer range means greater convenience.

Engineers in R&D see the same issues from a different perspective. They aim to achieve the highest efficiency by minimizing energy losses; for individual components, at the sub-systems level, and at the level of the entire vehicle.

The Basics of Electric Vehicle Testing

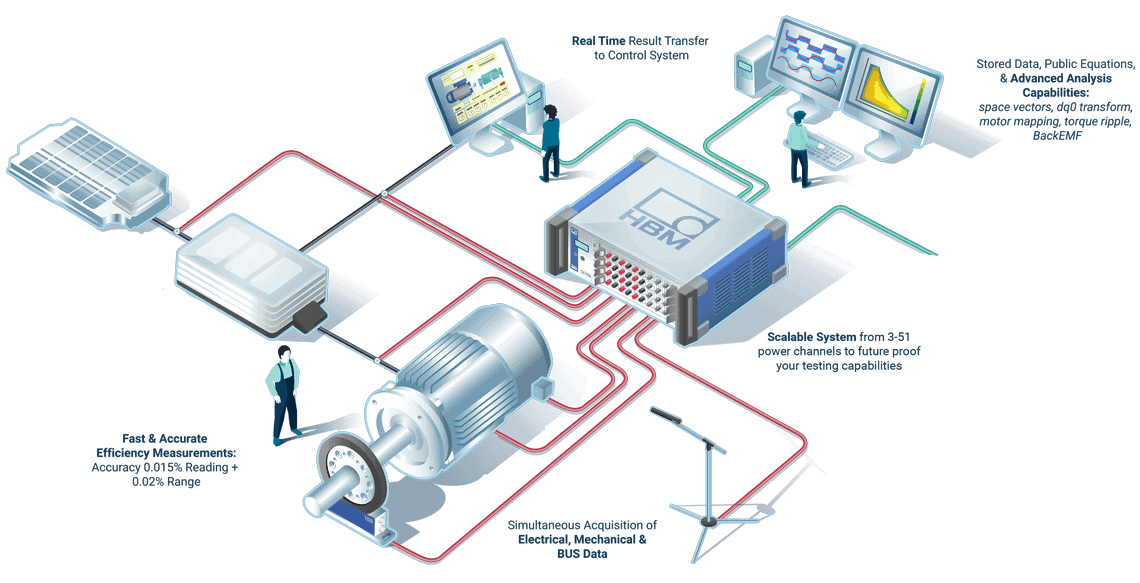

When Engineers examine the drivetrain, they consider more than just motor efficiency. Where do the energy losses occur? In transmission from the AC network to the battery? In the energy storage? In the conversion from DC battery back to AC again? In the inverter? Or the motor? Engineers seek to optimise the entire combination of battery inverter and motor that converts the electrical energy into mechanical power. Last but not least, they need to check that the motor controller, which regulates the communications between these three units, works correctly.

Difficulty of Calculating Electric Motor Efficiency

Calculating electric motor efficiency as the quotient of “electric power in” versus “mechanical power out” sounds easy. It’s not, because in practice such systems are highly dynamic. In fact, accurately measuring the power, and optimising the efficiency of inverters and electric motors under changing speeds and torque is one of the most demanding tasks in electric power testing.

Variables to Consider in Motor-Inverter Testing

The way these components cooperate impacts efficiency more than mere power. How do the individual components behave? How does that behaviour change under different circumstances (temperature, humidity) and in dynamic states (varying road conditions or driving styles)? And, of course, there are conflicting technical requirements like large bandwidths, a wide dynamic range and high measurement accuracies in a highly stressed EMC environment.

Physical Testing Vs. Computer Simulations

Computer simulations offer a theoretical indication of electric motor efficiency, but these need to be validated by extensive physical testing to make sure that calculated values match the evidence gained at the test bench – and that both reflect actual conditions in the real world. High-quality measurement data provides reliable insights that enable engineers to decide whether component, sub-systems or complete vehicles need to be validated by more testing, or whether they are ready to go into production.

The Growing Complexity of Electric Powertrain Testing

This is where the problem starts: the complexity within the component families is immense. Combining a powerful battery with an effective inverter and an efficient motor doesn’t automatically guarantee that a drive system is as efficient as it could be. Batteries range from 200-400 volts but can be as high as 600-800 volts. Inverter switches that operate at low frequencies will reduce losses, but they may become audible; higher frequencies result in higher losses and are limited by the physical switch sizes. Newly developed high frequency models are highly expensive and not yet robust.

Different Motor Types

The variety of electric motor types (permanent magnet, induction, wound field, or switched reluctance) multiplied by the range of motor sizes offers limitless possibilities. Still further complexity is possible through the use of multiple inverters, in effect creating machines with six or more phases. Each combination has its own individual benefits and downsides. Then comes the vehicle configuration: an electric vehicle can have between one and four traction motors, plus a host of smaller DC motors for auxiliary systems (windows, seats, etc.) all of which draw power from the batteries and impact the efficiency of the vehicle.

Differences Between Vehicles

Each individual vehicle is designed to meet a set of customer expectations that are clearly defined at the beginning of development. The expectations of a sports car driver, for example, in terms of range, comfort and driving behaviour are very different to the expectations of a small car driver. Testing must clarify whether the actual performance fails, meets or exceeds expectations for efficiency, losses and behaviour in each case.

Manufacturing Quirks

At the same time, motor manufacturers aim to balance design requirements against economic criteria. In addition to the unit cost of production, they also seek to reduce the effort invested in R&D via shorter test cycles and faster time-to-market.

The Need for Custom Powertrain Testing Workflows

Since there are hardly any standards for tests in the field of electromobility, every test set-up is adapted to the individual components under test. As every vehicle must be able to handle constant speed and load changes as well as load conditions (road conditions, drive styles, battery condition or ambient conditions like temperature and weather), these parameters need to be considered in the test set-up. As we have seen above, the scenario becomes even more complex for vehicles with not just one motor deriving a single axle, but at several axles with several motors. This level of complexity multiplies the number of measurements and the volume of data to be collected is expands in proportion.

Add to that the complex and time-consuming test bench build which is usually highly customized. Timely coordination and planning are therefore essential to ensure that deadlines for ensuing development steps up to series production will be met. To this end, all parts of the test bench must mesh smoothly. What can be done to meet all these requirements at the same time? The answer is to choose test bench equipment that seamlessly integrates into the test bench system; that is not only accurate, but also increases engineer productivity while supporting the need to deliver auditable results for validation and certification.