Safer EV Batteries using Multiphysics Simulation

Electric vehicles (EV) offer the exciting possibility to meet the world’s transportation demands in an environmentally sustainable way. Mass adoption could help reduce our reliance on fossil fuels, but the lithium-ion (Li-on) batteries that power them still present unique challenges to designers and engineers, primary among them – ensuring safety against battery fire. To improve the safety of Li-on batteries it is necessary to have an insight into all the complex, interconnected aspects of their behavior across both – normal and extreme – duty cycles. Altair is focused on developing a comprehensive

understanding of automotive battery safety issues through Altair Battery Designer project. It combines innovative design methods and tools to model and predict mechanical and short-term thermal response to mechanical abuses, providing accurate computational models and engineer-friendly methods to design a better battery.

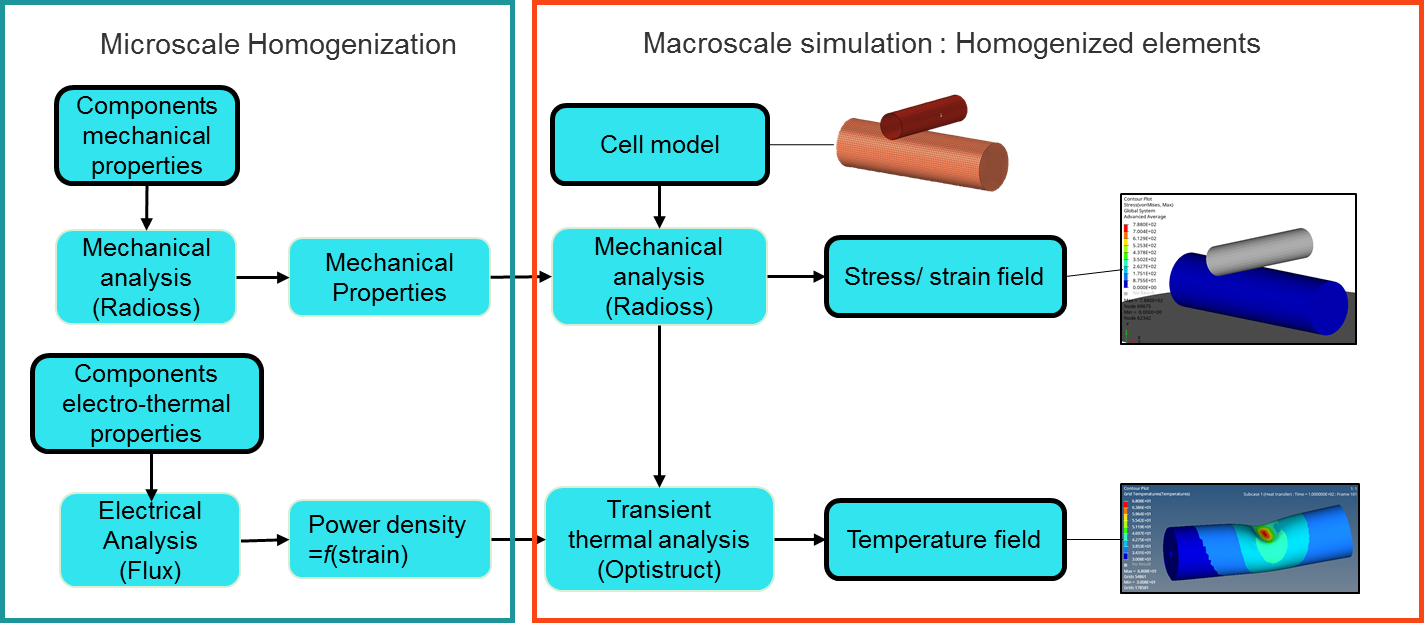

Based on the mechanical and electro-thermal experimental tests of battery cell components (anode, cathode, separator, etc.), homogenized properties of the cell can be identified using Altair RadiossTM and Altair FluxTM software. Used to predict whether the vehicle adheres to regulatory crash and impact regulations, Altair’s homogenization method enables the accurate simulation of a full electric vehicle, including a realistic deformable battery pack, to be run in less than one night. Once implemented, the design of the entire vehicle can be optimized, leading to a high degree of safety and a low-cost production.

The next step consists of calculating the thermal effect caused by deformations of materials inside the battery components to determine the risk of thermal runaway. Altair Flux can be used to perform the electro-thermal characterization of the homogenized element. Internal short circuits are considered based on a compressive strain criterion and the power loss in the material can be extracted from the tests. A transient heat transfer analysis is accomplished using Altair OptistructTM, exploiting the deformed shape of the battery calculated by Radioss and the power losses calculated from the homogenized element strain values.

The process involves several complex operations – numerical Multiphysics simulations including highly nonlinear structural dynamic analysis, transient thermal analysis, and electro-thermal interactions. It is therefore fundamental to validate the accuracy of the results and the predictivity of the process on simplistic applications before conducting it on a full-scale battery or electric vehicle design. In most cases, the calculation times are completed in just a few minutes on a laptop for the mechanical analysis and few seconds for the thermal analysis.

The mechanical and the thermal simulation results arising out of this solution all correlate well with the physical tests, which demonstrates that the process properly accounts for the multiphysics behavior. This method allows designers to quickly identify potential safety issues early in the battery design process, shortening development time and ultimately leading to the design of safer, more cost-effective, and better-performing electric vehicles. With the increased use of Li-on batteries for mobility solutions, verifying battery safety in extreme cases of impact and shock is an important issue. Using Altair Battery Designer solution, it is now possible to accurately predict the short-term mechanical and thermal behaviors of a battery under abusive loading in a short period of time. This unique process can be applied to multiple load cases such as crash, crush, deceleration, and impacts with and without penetration.

Find the detailed white paper at – Download Complete Article

( https://altair.com/resource/battery-designer-wp?lang=en )

Scan the QR code below to download eGuide to Accelerating e-Mobility to Realization