Water turbines keep on running with Rainpower

Engineering services’ expert develops unique measurement tool for runner blades

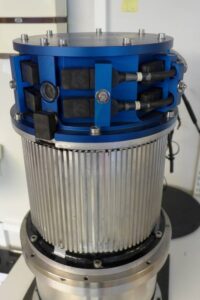

As runner blades are a critical component of water turbines, Rainpower has developed a new measurement tool – called a Flight Recorder – to accurately measure dynamic stress on these components, ensuring continuous operation under the harshest conditions.

The Flight Recorder is a battery-operated system, where all data is stored locally, negating the need for an underwater data transmission system. It measures strain on turbine blades, pressure distribution in the runner in different places, vibration on different locations and temperature on the runner surface, supplying data that is vital for calibration of data simulations and numerical analysis.

During development of the recorder, Rainpower approached test and measurement specialist, HBK for a solution on the Data Acquisition System (DAQ) part of the unit. HBK provided QuantumX units to collect data, along with a CX22 industrial computer/data recorder that contained a flash memory. The system, which runs with catman software, was mounted in a tailor-made framing system, then placed inside waterproof housing with waterproof subsea connectors.

Before testing, HBM strain gauges are applied to runner blades on predefined spots, and the other transducers are mounted on their appropriate places. All transducers are then connected to the Flight Recorder with watertight cables, and the unit is then mounted onto the hub of the runner. Before filling the turbine with water, the recorder is switched on and the catman program starts collecting data.

The QuantumX DAQ systems provides reliable data acquisition of different physical quantities and sensor technologies. It is also user friendly and portable, so is easy to move around and fit in confined spaces.

“As a company dedicated to testing, we needed to choose the right equipment for this project. So, following a market review, we opted to use HBM components. HBM provided us with excellent service and knowledge in the strain gauge market, which was an especially important aspect to us”, explains Kjell Sivertsen, Discipline Manager Lab Technology and Equipment, Rainpower AS, Turbine Laboratory, Trondheim.

With the development of the Flight Recorder proving such a success, Rainpower AS plans to undertake a further three to four tests later the coming year, both in Norway and Sweden.

The full case study is available here: https://www.hbm.com/index.php?id=10423&L=0

About Hottinger Brüel & Kjær

Industry market leaders HBM and Brüel & Kjær have joined forces as Hottinger Brüel & Kjaer to form the world’s foremost provider of integrated test, measurement, control and simulation solutions.

Hottinger Brüel & Kjaer provides a complete portfolio of solutions across the test and measurement product life cycle, that unites the physical world of sensors, testing and measurement with the digital world of simulation, modelling software and analysis. By creating a scalable and open data acquisition hardware, software and simulation ecosystem, product developers can cut time-to- market, drive innovation and take the lead in a highly competitive global marketplace.

For more information visit www.hbkworld.com

Email: sundaresan.sridharan@hbkworld.com